Machining

With over sixty years of shop practice, and the completion of over 1000 jobs a year, Hamill Machine Co. Inc. has prided itself on its ability to build with the times, and trend set with modern technologies to stay ahead of the competition. We operate by means of a variety of interconnected software systems & CNC Machines, each suited for different operational sets. Hamill’s CNC cell includes a 4th Axis CINCINATTI CNC HORIZONTAL MACHINING CENTER, MONARCH 1418 VERTICAL CNC and CNC LATHE.

These machines are used alongside conventional machines such as Bridgeport milling machines, lathes, key seaters, drill presses and other necessary shop tools all housed in our modern 8000 sq.ft. facility equipped with overhead cranes throughout. Hamill Machine has the tools and manpower to get any machining operation completed to your quality standards, meeting your tight deadlines with around the clock service.

CNC/Milling machines: UP TO 100″ X 40″ X 40″

CNC Lathe: UP TO 12″ DIA

Turning: UP TO 30″ DIA

Machining Projects

Co-ordinate Measuring Machine (CMM)

Machining & Millwright

Pump Overhaul

Machining & Millwright

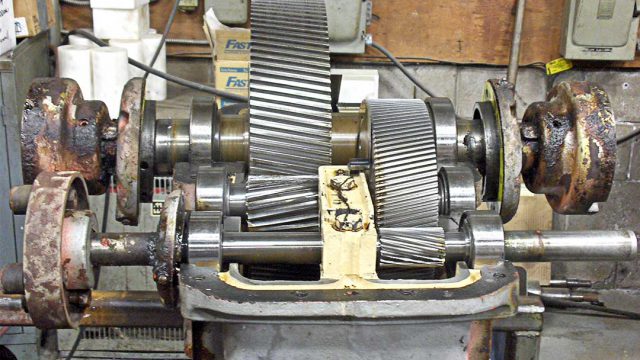

Gearbox Overhaul

Machining & Millwright

Machining 3

Machining & Millwright

Machining 2

Machining & Millwright

Machining 1

Machining & Millwright

Addamatic Shaft Assy Machining

Machining & Millwright

Welding & Fabricating

Performances of Large missions are always governed by the functioning of small factors. Strong welding joints, a subset of fabrication services, is key to your large project. At Hamill, our certified welding team is equipped to undergo complex shapes & material welding tasks to meet your fabrication requirement.

Hamill’s excellent custom design and engineering facilities is superseded by modern welding and fabrication facility.

We not only perform basic types of welding (Stick welding, MIG welding, TIG welding) but also are one of the few shops to offers plastic welding. This service is also available for on-site tank or part repair. in addition to these commercial welding projects, we also perform mobile welding operations such as welding repairs with our mobile unit for immovable or heavy equipment such as Niagara’s own Made of the Mist.

Welding & Fabricating Projects

Millwrighting

We provide modern millwrighting services to support the manufacturing industry. Our modern industrial mechanics are available around the clock for emergency services in case of failure or breakdown or for scheduled work shifts, to optimize your company’s production schedule at your convenience. Hamill Machine’s competent and certified millwright team are backed by licensed electricians, welders, and machinists to aide in the completion of any project requirements.

And our design and management team are more than eager to consult with customers on any project, no matter the scope or size. With over 60 years in business we have acquired the experience and equipment to complete jobs to exacting standards, and know a job is not complete until the customer is satisfied. Our millwrights will respect your property, employees and their work assuring you piece of mind service 24 hours a day.

Millwrighting Projects

3D Engineering

Hamill Machine uses 3D design software to design, modify and build your products. This software is compatible with virtually all different engineering programs and software. A few services this allows us to do are build and analyze complete mechanical systems, develop drawings for fabrication, 3D mechanical design, sheet metal design tube and pipe design.

A great example of using our 3D engineering is our winery layouts. Wineries have several kegs to store and huge tanks. We work with you to design a complete layout that meets your needs. This ensures proper layout and makes the building process easy and reliable.

3D Engineering Projects

No Projects Found.

Dynamic Balancing

We can dynamically balance fans up to 36″ in diameter. We balance to any G code required. Our machine is capable of holding up to 4000 lbs.

Dynamic Balancing Projects

Laser Cutting

Laser cutting allows us to customize several projects. It is a huge time and cost savings for our customers to not outsource our laser cutting jobs. We can cut up to 3/8″ steel, 1/8″ stainless steel, 1″ plastic, wood and glass.